Imuzak – a solution company that makes the impossible possible.

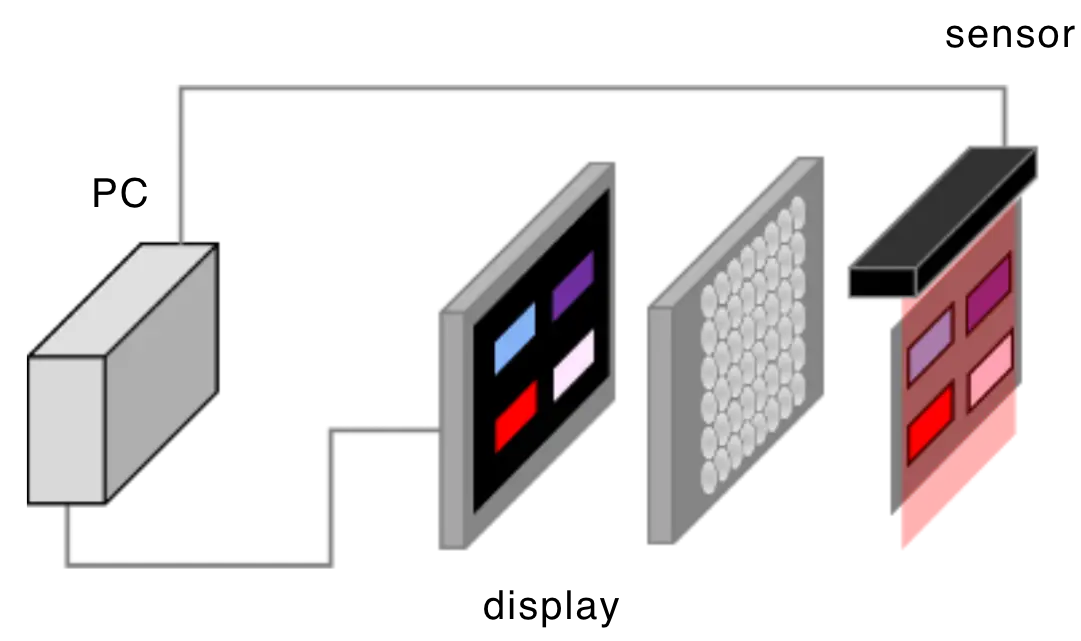

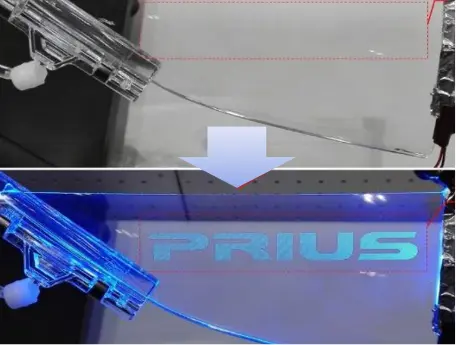

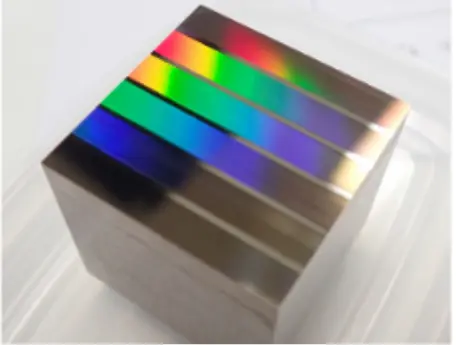

IMUZAK provides solutions that make the impossible possible by optical design, nanotechnology (machine processing, laser processing, semiconductor processing) and know-how, that originally came from our molding technology.

Efforts of IMUZAK

We design molds, microfabricate curved surfaces, and create prototypes to help you understand our technology. We also create prototypes.

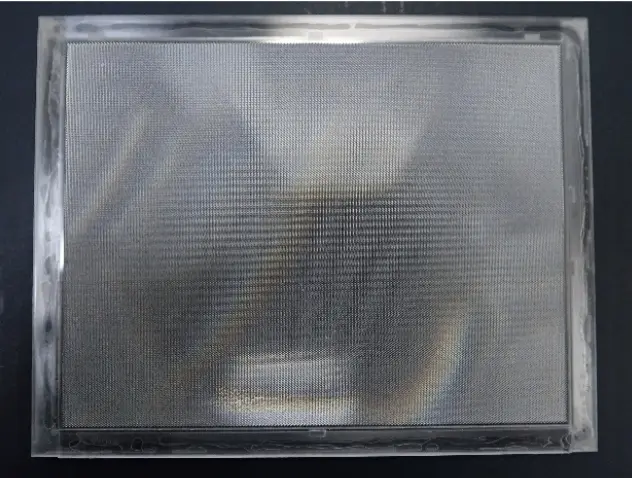

As an example, we have developed an optical element with a moth-eye structure by using a special mold process to create an antireflection structure on a curved surface and transfer it to the surface of a plastic part.By transferring this structure onto the surface of plastic parts, we have developed an optical element with a moth-eye structure.

We are also developing hydrophilic surface structures using the same technology.

IMUZAK aims to be a company that continues to disseminate manufacturing innovations learned from the natural world from the land of Yamagata.

Translated with www.DeepL.com/Translator (free version)